1. Brazeability

Thepa ea brazing ea aluminium le lisebelisoa tsa aluminium e futsanehile, haholo-holo hobane filimi ea oxide e holim'a metsi e thata ho e tlosa.Aluminium e na le kamano e ntle ea oksijene.Ho bonolo ho etsa filimi ea oxide e teteaneng, e tsitsitseng le e phahameng e qhibilihisang Al2O3 holim'a metsi.Ka nako e ts'oanang, lisebelisoa tsa aluminium tse nang le magnesium li tla boela li thehe filimi e tsitsitseng ea oxide MgO.Li tla thibela ka botebo ho kolobisa le ho ata ha solder.Le ho thata ho tlosa.Nakong ea brazing, ts'ebetso ea brazing e ka etsoa feela ka phallo e nepahetseng.

Taba ea bobeli, ts'ebetso ea aluminium le aluminium alloy brazing e thata.Sebaka se qhibilihang sa aluminium le alloy alloy ha se fapane haholo le sa tšepe ea ho tlatsa tšepe e sebelisoang.Boemo ba mocheso oa boikhethelo bakeng sa brazing bo moqotetsane haholo.Ho laola mocheso o fokolang o sa lokelang ho bonolo ho baka mocheso o feteletseng kapa esita le ho qhibiliha ha tšepe ea motheo, ho etsa hore ho be thata ho tiisa.Li-alloys tse ling tsa aluminium tse matlafalitsoeng ke phekolo ea mocheso li tla boela li bake lintho tse nolofatsang tse kang ho tsofala kapa ho tsuba ka lebaka la ho futhumatsa ha brazing, e leng ho tla fokotsa thepa ea manonyeletso a brazed.Nakong ea ho chesa lelakabe, ho thata ho ahlola mocheso hobane 'mala oa aluminium alloy ha o fetohe nakong ea ho futhumatsa, e leng ho eketsang litlhoko tsa boemo ba ts'ebetso ea opereishene.

Ho feta moo, ho hanyetsa kutu ha aluminium le aluminium alloy brazed manonyeletso ho angoa habonolo ke litšepe tsa ho tlatsa le ho phalla.Monyetla oa elektrode oa aluminium le alloy alloy o fapane haholo le oa solder, e leng ho fokotsang ho hanyetsa ho bola ha motsoako, haholo-holo bakeng sa motsoako o bonolo oa soldering.Ho feta moo, boholo ba li-fluxes tse sebelisoang ho beng ha aluminium le li-alloys tsa aluminium li na le ho bola ho matla.Esita le haeba li hloekisoa ka mor'a ho qhoqhoa, tšusumetso ea li-fluxes ho hanyetsa ho bola ha manonyeletso e ke ke ea felisoa ka ho feletseng.

2. Lisebelisoa tsa ho chesoa

(1) Brazing ea aluminium le li-alloys tsa aluminium ke mokhoa o sa sebelisoeng hangata, hobane sebopeho le bokhoni ba elektrode ba tšepe ea brazing le tšepe ea motheo li fapane haholo, ho leng bonolo ho baka kutu ea electrochemical ea lenonyeletso.Solder e bonolo e sebelisa solder e thehiloeng ho zinc le tin lead solder, e ka aroloa ka solder e tlase ea mocheso (150 ~ 260 ℃), solder ea mocheso o mahareng (260 ~ 370 ℃) le solder e phahameng ea mocheso (370 ~ 430 ℃) ho latela mocheso oa mocheso.Ha tin lead solder e sebelisoa 'me koporo kapa nickel e pentiloe esale pele holim'a aluminium bakeng sa brazing, kutu e ka thijoa sehokelong sa lenonyeletso, e le ho ntlafatsa ho hanyetsa ho bola ha lenonyeletso.

Brazing ea aluminium le alloys ea aluminium e sebelisoa haholo, joalo ka tataiso ea filthara, evaporator, radiator le likarolo tse ling.Ke litšepe tsa aluminium feela tse ka sebelisoang bakeng sa ho betla ha aluminium le lialloys tsa aluminium, tseo har'a tsona litšepe tsa aluminium silicon filler li sebelisoang haholo.Sebaka se ikhethileng sa ts'ebeliso le matla a ho kuta a manonyeletso a brazed a bonts'itsoe ho Lethathamo la 8 le tafoleng ea 9 ka ho latellana.Leha ho le joalo, ntlha ea ho qhibiliha ea solder ena e haufi le ea tšepe ea motheo, kahoo mocheso oa mocheso o lokela ho laoloa ka thata le ka nepo nakong ea ho betla ho qoba ho chesa haholo kapa esita le ho qhibiliha ha tšepe ea motheo.

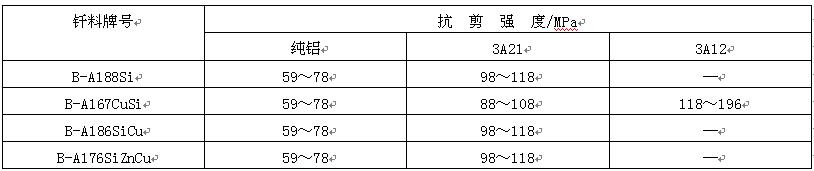

Lethathamo la 8 la ts'ebeliso ea litšepe tsa brazing filler bakeng sa aluminium le alloys ea aluminium

Tafole 9 matla a ho kuta a aluminium le alloy alloy alloy a kopantsoeng ka tšepe ea aluminium silicon filler

Aluminium silicon solder hangata e fanoa ka mokhoa oa phofo, peista, terata kapa lakane.Maemong a mang, lipoleiti tse kopantsoeng tsa solder tse nang le aluminium e le motheo le aluminium silicon solder ha ho ntse ho sebelisoa likoahelo.Mofuta ona oa poleiti e kopantsoeng ea solder e entsoe ka mokhoa oa hydraulic mme hangata e sebelisoa e le karolo ea likarolo tsa brazing.Nakong ea brazing, tšepe e tlatsang brazing holim'a poleiti e kopantsoeng ea qhibiliha ebe e phalla tlas'a ketso ea capillary le matla a khoheli ho tlatsa lekhalo le kopantsoeng.

(2) Flux le khase e sireletsang bakeng sa aluminium le aluminium alloy brazing, flux e khethehileng e atisa ho sebelisoa ho tlosa filimi.Organic flux e thehiloeng ho triethanolamine, joalo ka fs204, e sebelisoa ka solder e bonolo ea mocheso o tlase.Molemo oa phallo ena ke hore e na le phello e fokolang ea kutu holim'a tšepe ea motheo, empa e tla hlahisa khase e ngata, e tla ama ho kolobisa le ho baka ha solder.The reactive flux e thehiloeng ho zinki chloride, joalo ka fs203 le fs220a, e sebelisoa ka mocheso o mahareng le mocheso o phahameng oa solder e bonolo.The reactive flux e senya haholo, 'me masalla a eona a tlameha ho tlosoa ka mor'a ho qhoqhoa.

Hona joale, ho belisoa ha aluminium le li-alloys tsa aluminium ho ntse ho laoloa ke ho tlosoa ha filimi ea flux.Motsoako oa brazing o sebelisitsoeng o kenyelletsa flux e thehiloeng ho chloride le fluoride e thehiloeng ho fluoride.Chloride e thehiloeng ho flux e na le matla a matla a ho tlosa filimi ea oxide le metsi a matle, empa e na le phello e kholo ea ho senya tšepe ea motheo.Masala a eona a tlameha ho tlosoa ka ho feletseng ka mor'a ho betla.Fluoride e thehiloeng ho flux ke mofuta o mocha oa phallo, o nang le phello e ntle ea ho tlosa filimi 'me ha e na kutu ho tšepe ea motheo.Leha ho le joalo, e na le ntlha e phahameng ea ho qhibiliha le botsitso bo fokolang ba mocheso, 'me e ka sebelisoa feela ka aluminium solder ea silicon.

Ha brazing aluminium le aluminium alloys, vacuum, neutral kapa inert atmosphere e atisa ho sebelisoa.Ha ho sebelisoa vacuum brazing, tekanyo ea vacuum hangata e tla fihla ho 10-3pa.Ha naetrojene kapa khase ea argon e sebelisoa bakeng sa ts'ireletso, bohloeki ba eona bo tlameha ho ba bo phahameng haholo, 'me ntlha ea phoka e be ka tlase ho -40 ℃

3. Theknoloji ea brazing

Brazing ea aluminium le li-alloys tsa aluminium li na le litlhoko tse phahameng tsa ho hloekisa bokaholimo ba mosebetsi.E le ho fumana boleng bo botle, letheba la oli le filimi ea oxide e holim'a metsi e tlameha ho tlosoa pele ho brazing.Tlosa letheba la oli holim'a metsi ka tharollo ea metsi a Na2CO3 ka mocheso oa 60 ~ 70 ℃ bakeng sa 5 ~ 10min, ebe o hlatsoa ka metsi a hloekileng;Filimi ea oxide e holim'a metsi e ka tlosoa ka ho etching ka tharollo ea metsi a NaOH ka mocheso oa 20 ~ 40 ℃ bakeng sa 2 ~ 4min, ebe e hlatsoa ka metsi a chesang;Ka mor'a ho tlosa letheba la oli le filimi ea oxide holim'a metsi, mosebetsi oa ho sebetsa o tla phekoloa ka tharollo ea metsi a HNO3 bakeng sa 2 ~ 5min, ebe e hloekisoa metsing a phallang 'me qetellong e omisitsoe.Sesebelisoa se sebetsoang ka mekhoa ena se ke ke sa angoa kapa sa silafatsoa ke litšila tse ling, 'me se tla ts'oaroa nakong ea 6 ~ 8h.Ho molemo ho itlosa bolutu hang ha ho khoneha.

Mekhoa ea ho betla ea aluminium le li-alloys tsa aluminium haholo-holo e kenyelletsa ho chesoa ha lelakabe, ho tiisa tšepe ea tšepe le ho besa sebōpi.Mekhoa ena ka kakaretso e sebelisa flux ho brazing, 'me e na le litlhoko tse thata mabapi le mocheso oa mocheso le nako ea ho ts'oara.Nakong ea ho besa ha lelakabe le tšepe e tiisang tšepe, qoba ho futhumatsa phallo ka kotloloho mohloling oa mocheso ho thibela mocheso hore o se ke oa chesa le ho hloleha.Kaha aluminium e ka qhibiliha ka solder e bonolo e nang le zinki e ngata, ho futhumatsa ho lokela ho emisoa hang ha lenonyeletso le thehoa ho qoba ho senya tšepe ea motheo.Maemong a mang, brazing ea aluminium le aluminium alloys ka linako tse ling ha e sebelise flux, empa e sebelisa mekhoa ea ultrasonic kapa scraping ho tlosa filimi.Ha u sebelisa scraping ho tlosa filimi bakeng sa brazing, qala ka ho futhumatsa workpiece ho mocheso oa mocheso, ebe o hlakola karolo ea brazing ea workpiece ka qetello ea molamu oa solder (kapa sesebelisoa sa ho hlakola).Ha o ntse o pshatla filimi ea oxide e holim'a metsi, qetellong ea solder e tla qhibiliha ebe e kolobisa tšepe ea motheo.

Mekhoa ea brazing ea li-alloys tsa aluminium le aluminium haholo-holo e kenyelletsa ho besa ha lelakabe, ho besa sebōpi, brazing ea dip brazing, vacuum brazing le khase e sirelelitsoeng ka khase.Flame brazing e sebelisoa haholo bakeng sa li-workpieces tse nyane le tlhahiso ea sekotoana se le seng.E le ho qoba ho hlōleha ha phallo ka lebaka la ho kopana pakeng tsa litšila acetylene le phallo ha u sebelisa oxyacetylene lelakabe, ho loketse ho sebelisa peterole petelitsoe moea lelakabe ka ho fokotsa hanyenyane ho thibela oxidation ea tšepe botlaaseng.Nakong ea ho chesoa ka mokhoa o khethehileng, mocheso oa brazing le tšepe ea ho tlatsa e ka behoa sebakeng sa brazed esale pele 'me e futhumetse ka nako e le' ngoe le mosebetsi oa ho sebetsa;Sebaka sa mosebetsi se ka boela sa futhumatsoa ho mocheso oa brazing pele, ebe solder e kolobisitsoeng ka flux e ka romeloa sebakeng sa brazing;Ka mor'a hore tšepe ea flux le filler e qhibilihe, lelakabe le futhumatsang le tla tlosoa butle-butle ka mor'a hore tšepe ea ho tlatsa e tlatsitsoe ka ho lekana.

Ha o betsa aluminium le alloy ea aluminium ka seboping sa moea, tšepe ea brazing e tla be e lokiselitsoe esale pele, 'me phallo ea brazing e tla qhibiliha ka metsing a qhibilihisitsoeng ho lokisa tharollo e teteaneng e nang le motsoako oa 50% ~ 75%, ebe e koahetsoe kapa e fafatsoa holim'a. bokahodimo bo benyang.Palo e nepahetseng ea phofshoana ea phofshoana e ka koaheloa holim'a tšepe ea brazing filler le brazing surface, ebe weldment e kopaneng e tla beoa ka seboping bakeng sa ho futhumatsa brazing.E le ho thibela tšepe ea motheo ho chesa haholo kapa esita le ho qhibiliha, mocheso oa mocheso o lokela ho laoloa ka thata.

Paste kapa foil solder hangata e sebelisoa bakeng sa dip brazing ea aluminium le alloys ea aluminium.Sesebelisoa se kopaneng se tla futhumatsoa pele se belisoa ho etsa hore mocheso oa sona o be haufi le mocheso oa brazing, ebe o qoelisoa ka har'a brazing flux bakeng sa brazing.Nakong ea brazing, mocheso oa brazing le nako ea brazing e lokela ho laoloa ka thata.Haeba mocheso o phahame haholo, tšepe ea motheo e bonolo ho qhaqha 'me solder e bonolo ho lahleheloa;Haeba mocheso o le tlase haholo, solder ha e qhibilihe ka ho lekaneng, 'me lebelo la ho qhibiliha le fokotseha.Mocheso oa mocheso o tla khethoa ho latela mofuta le boholo ba tšepe ea motheo, sebopeho le ntlha ea ho qhibiliha ea tšepe e tlatsang, 'me hangata e pakeng tsa mocheso oa liquidus oa tšepe ea ho tlatsa le mocheso oa solidus oa tšepe ea motheo.Nako ea ho qoelisa ea workpiece ka bateng ea flux e tlameha ho netefatsa hore solder e ka qhibiliha ka ho feletseng le ho phalla, 'me nako ea ho tšehetsa ha ea lokela ho ba nako e telele haholo.Ho seng joalo, karolo ea silicon e ka har'a solder e ka 'na ea hasana ka har'a tšepe ea motheo, ea etsa hore tšepe ea motheo e haufi le seam brittle.

Ka vacuum brazing ea aluminium le li-alloys tsa aluminium, li-activators tsa tšepe li atisa ho sebelisoa ho fetola filimi ea oxide e holim'a aluminium le ho netefatsa ho koloba le ho hasana ha solder.Magnesium e ka sebelisoa ka kotloloho holim'a sesebelisoa ka mokhoa oa likaroloana, kapa ea kenngoa sebakeng sa brazing ka mokhoa oa mouoane, kapa magnesium e ka eketsoa ho solder ea aluminium ea silicon e le motsoako oa alloy.Bakeng sa workpiece e nang le sebopeho se rarahaneng, e le ho etsa bonnete ba hore phello e feletseng ea mouoane oa magnesium holim'a tšepe ea motheo le ho ntlafatsa boleng ba brazing, mehato ea ts'ebetso ea ts'ireletso ea sebakeng seo e atisa ho nkoa, ke hore, workpiece e qala ho kenngoa ka lebokoseng la tšepe e sa hloekang (hangata. e tsejoang ka hore ke lebokose la tšebetso), ebe e kenngoa ka seboping sa vacuum bakeng sa ho futhumatsa brazing.Vacuum Brazed Aluminium le manonyeletso a aluminium alloy a na le manonyeletso a boreleli a boreleli, 'me ha a hloke ho hloekisoa ka mor'a ho betla;Leha ho le joalo, lisebelisoa tsa vacuum brazing li theko e boima, 'me mouoane oa magnesium o silafatsa sebōpi haholo, kahoo se hloka ho hloekisoa le ho hlokomeloa khafetsa.

Ha ho betla aluminium le li-alloys tsa aluminium moeeng o sa nke lehlakore kapa o sa sebetseng, activator ea magnesium kapa flux e ka sebelisoa ho tlosa filimi.Ha magnesium activator e sebelisoa ho tlosa filimi, palo ea magnesium e hlokahalang e tlase haholo ho feta ea vacuum brazing.Ka kakaretso, w (mg) ke hoo e ka bang 0.2% ~ 0.5%.Ha litaba tsa magnesium li phahame, boleng ba motsoako bo tla fokotseha.NOCOLOK brazing mokhoa o sebelisang fluoride flux le nitrogen protection ke mokhoa o mocha o ntlafalitsoeng ka potlako lilemong tsa morao tjena.Kaha masala a fluoride flux ha a amohele mongobo 'me ha a senyehe ho aluminium, mokhoa oa ho tlosa masala a flux ka mor'a ho qhoqhoa o ka tlosoa.Tlas'a tšireletso ea naetrojene, ke palo e nyane feela ea fluoride e lokelang ho koaheloa, tšepe ea filler e ka kolobisa tšepe ea motheo, 'me ho bonolo ho fumana manonyeletso a boleng bo holimo.Hajoale, mokhoa ona oa NOCOLOK oa brazing o sebelisitsoe tlhahisong e kholo ea radiator ea aluminium le likarolo tse ling.

Bakeng sa aluminium le alloy alloy e kentsoeng ka flux ntle le fluoride flux, masalla a flux a tlameha ho tlosoa ka ho feletseng ka mor'a ho belisoa.Masala a organic brazing flux bakeng sa aluminium a ka hlatsuoa ka litharollo tsa manyolo tse kang methanol le trichlorethylene, a se ke a sebelisoa ka sodium hydroxide aqueous solution, 'me qetellong a hloekisoe ka metsi a chesang le a batang.Chloride ke masala a brazing flux bakeng sa aluminium, e ka tlosoang ho latela mekhoa e latelang;Ntlha ea pele, inela ka metsing a chesang ka 60 ~ 80 ℃ bakeng sa 10min, hloekisa ka hloko masala holim'a motsoako oa brazed ka borashe, 'me ue hloekise ka metsi a batang;Ebe u e kenya ka har'a 15% ea nitric acid aqueous solution bakeng sa 30min, 'me qetellong ue hlatsoe ka metsi a batang.

Nako ea poso: Jun-13-2022