1. Lisebelisoa tsa ho chesoa

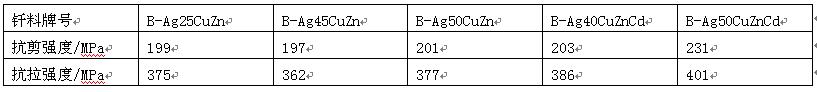

(1)Brazing ea tšepe ea carbon le tšepe e tlaase ea alloy e kenyelletsa ho betla ha bonolo le ho tiisa ka thata.Solder e sebelisoang haholo ho solder e bonolo ke tin lead solder.Ho koloba ha solder ena ho tšepe ho eketseha ka ho eketseha ha tin, kahoo solder e nang le lisebelisoa tse phahameng tsa tin e lokela ho sebelisoa bakeng sa ho tiisa manonyeletso.Fesn2 intermetallic compound layer e ka thehwa sehokelong pakeng tsa thini le tshepe ka solder ya tin lead.E le ho qoba ho thehoa ha motsoako karolong ena, mocheso oa brazing le nako ea ho tšoara o lokela ho laoloa hantle.Matla a ho kuta a maqhama a tšepe a k'habone a kopantsoeng ka li-solders tse 'maloa tse tloaelehileng tsa tin a bonts'itsoeng ho Lethathamo la 1. Har'a tsona, matla a kopantsoeng a kopantsoeng ka 50% w (SN) ke a phahameng ka ho fetisisa, 'me matla a kopantsoeng a kopantsoeng le antimony free solder a phahame ho feta. hore ka antimony.

Tafole 1 ea matla a ho kuta a likhokahano tsa tšepe ea k'habone tse kentsoeng ka tšepe ea lead solder

Ha ho etsoa tšepe ea carbon le tšepe e tlase ea alloy, ho sebelisoa haholo koporo e hloekileng, zinki ea koporo le tšepe ea koporo ea zinc brazing.Koporo e hloekileng e na le ntlha e phahameng ea ho qhibiliha 'me e bonolo ho oxidize tšepe ea motheo nakong ea brazing.E sebelisoa haholo bakeng sa brazing e sirelelitsoeng ka khase le vacuum brazing.Leha ho le joalo, hoa lokela ho hlokomeloa hore lekhalo pakeng tsa manonyeletso a brazed le lokela ho ba tlase ho 0.05mm ho qoba bothata ba hore lekhalo le kopantsoeng le ke ke la tlatsoa ka lebaka la metsi a matle a koporo.Lithako tsa tšepe tsa carbon le alloy tse tlase tse kentsoeng ka koporo e hloekileng li na le matla a phahameng.Ka kakaretso, matla a ho kuta ke 150 ~ 215mpa, ha matla a tensile a ajoa pakeng tsa 170 ~ 340mpa.

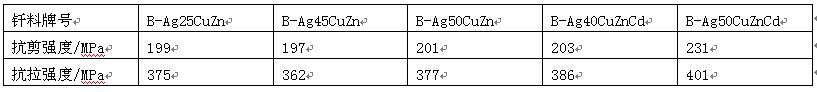

Ha ho bapisoa le koporo e hloekileng, ntlha e qhibilihang ea koporo ea zinki e fokotseha ka lebaka la ho eketsoa ha Zn.E le ho thibela mouoane oa Zn nakong ea brazing, ka lehlakoreng le leng, chelete e nyenyane ea Si e ka ekeletsoa ho solder ea koporo ea zinki;Ka lehlakoreng le leng, mekhoa ea ho futhumatsa e potlakileng e tlameha ho sebelisoa, joalo ka ho chesoa ha lelakabe, brazing ea induction le dip brazing.Manonyeletso a tšepe ea carbon le tšepe e tlase ea alloy e kentsoeng ka tšepe ea koporo ea zinki e na le matla a matle le polasetiki.Ka mohlala, matla a tsitsipano le matla a ho kuta a metsoako ea tšepe ea carbon e entsoeng ka tšepe ea b-cu62zn e fihla ho 420MPa le 290mpa.Sebaka se qhibilihang sa solder ea silevera ea koporo e tlase ho feta ea koporo ea zinki, e loketseng bakeng sa ho cheselletsa nale.Tšepe ena ea li-filler e loketse ho chesoa ha lelakabe, ho kenya letsoho le ho chesoa ha sebōpi sa carbon steel le tšepe e tlaase ea alloy, empa litaba tsa Zn li lokela ho fokotsoa ka hohle kamoo ho ka khonehang nakong ea ho chesa sebōpi, 'me lebelo la ho futhumatsa le lokela ho eketseha.Brazing carbon steel le tšepe e tlase ea alloy e nang le tšepe ea silevera ea koporo ea zinki e ka fumana manonyeletso ka matla a matle le polasetiki.Lintlha tse khethehileng li thathamisitsoe ho Lethathamo la 2.

Letlapa la 2 la matla a maqhama a tšepe e tlase a k'habone a kentsoeng ka solder ea zinki ea koporo ea silevera

(2) Flux: flux kapa khase e sireletsang e tla sebelisoa bakeng sa tšepe ea carbon steel le tšepe e tlaase ea alloy.Flux hangata e khethoa ke tšepe e khethiloeng ea ho tlatsa le mokhoa oa brazing.Ha tin lead solder e sebelisoa, mokelikeli o tsoakiloeng oa zinc chloride le ammonium chloride o ka sebelisoa e le flux kapa flux e 'ngoe e khethehileng.Masala a phallo ena hangata a senya haholo, 'me lenonyeletso le lokela ho hloekisoa ka thata ka mor'a ho chesoa.

Ha ho besoa ka tšepe ea koporo ea zinki, ho tla khethoa fb301 kapa fb302 flux, ke hore, borax kapa motsoako oa borax le boric acid;Ha ho chesa mollo, motsoako oa methyl borate le formic acid e ka boela ea sebelisoa e le brazing flux, moo mouoane oa B2O3 o bapalang karolo ea ho tlosa filimi.

Ha tšepe ea tšepe ea koporo ea koporo e sebelisoa, fb102, fb103 le fb104 brazing fluxes e ka khethoa, ke hore, motsoako oa borax, boric acid le fluoride tse ling.Masala a phallo ena a senya ho isa bohōleng bo itseng 'me a lokela ho tlosoa ka mor'a ho qhoqhoa.

2. Theknoloji ea brazing

Sebaka se lokelang ho chesetsoa se tla hloekisoa ka mekhoa ea mechine kapa ea lik'hemik'hale ho netefatsa hore filimi ea oxide le lintho tse phelang li tlosoa ka ho feletseng.Sebaka se hloekisitsoeng ha sea lokela ho ba se thata haholo 'me se se ke sa khomarela lithapo tsa tšepe kapa litšila tse ling.

Tšepe ea carbon le tšepe e tlase ea alloy e ka ts'oaroa ka mekhoa e fapaneng e tloaelehileng ea brazing.Nakong ea ho chesoa ha malakabe, lelakabe le sa nke lehlakore kapa le fokotsang hanyenyane le lokela ho sebelisoa.Nakong ea ts'ebetso, ho futhumatsa ka kotloloho ea tšepe ea filler le flux ka lelakabe ho lokela ho qojoa ka hohle kamoo ho ka khonehang.Mekhoa ea ho futhumatsa e potlakileng joalo ka brazing ea induction le dip brazing e loketse haholo bakeng sa brazing ea tšepe e tingoeng le e halefileng.Ka nako e ts'oanang, ho tima kapa ho chesa ka mocheso o tlase ho feta mocheso ho lokela ho khethoa ho thibela ho nolofatsa tšepe ea motheo.Ha brazing low alloy high-power steel sepakapaka se sireletsang, ha ho hlokehe bohloeki bo phahameng feela ba khase, empa hape le phallo ea khase e tlameha ho sebelisoa ho netefatsa ho kolobisa le ho hasana ha tšepe ea filler holim'a tšepe ea motheo.

Phallo e setseng e ka tlosoa ka mekhoa ea lik'hemik'hale kapa ea mechine.Masala a organic brazing flux a ka hlakoloa kapa a hloekisoa ka peterole, joala, acetone le li-solvents tse ling tsa manyolo;Masala a matla a senyang a kang zinc chloride le ammonium chloride a tla fokotsoa ka tharollo ea metsi a NaOH pele, ebe a hloekisoa ka metsi a chesang le a batang;Boric acid le masala a boric acid flux a thata ho a tlosa, 'me a ka rarolloa feela ka mekhoa ea mechine kapa ho qoelisoa ka nako e telele metsing a ntseng a phahama.

Nako ea poso: Jun-13-2022