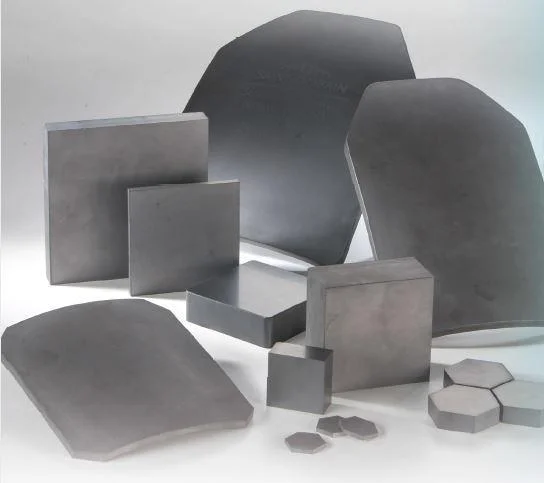

Li-ceramics tsa silicon carbide li na le matla a mocheso o phahameng, ho hanyetsa mocheso o phahameng oa oxidation, khanyetso e ntle ea ho apara, botsitso bo botle ba mocheso, coefficient e nyenyane ea katoloso ea mocheso, mocheso o phahameng oa mocheso, boima bo phahameng, ho hanyetsa mocheso, k'hemik'hale ea kutu ea lik'hemik'hale le lintho tse ling tse babatsehang.E sebelisitsoe haholo likoloing, metjhini, ts'ireletso ea tikoloho, theknoloji ea sefofane, lisebelisoa tsa elektroniki tsa tlhahisoleseling, matla le likarolo tse ling, 'me e fetohile ceramic e ke keng ea nkeloa sebaka e nang le ts'ebetso e ntle haholo mafapheng a mangata a indasteri.Joale e re ke u bontše!

Ho qoela ka ntle ho khatello

Sintering e senang khatello e nkuoa e le mokhoa o ts'episang ka ho fetesisa oa SiC sintering.Ho ea ka mekhoa e fapaneng ea sintering, sintering e se nang khatello e ka aroloa ka sintering e tiileng-mohato le mokelikeli-phase sintering.Ka ultra-fine β- A palo e nepahetseng ea B le C (litekanyo tsa oksijene tse ka tlase ho 2%) li ile tsa kenngoa ho SiC phofo ka nako e le 'ngoe, le s.proehazka e ile ea tšeloa ho SiC sintered 'mele o nang le letsoalo le phahameng ho feta 98% ho 2020 ℃.A. Mulla et al.Al2O3 le Y2O3 li ne li sebelisoa e le li-additives le li-sintered ho 1850-1950 ℃ bakeng sa 0.5 μ m β- SiC (karolo ea likaroloana e na le palo e nyenyane ea SiO2).Tekanyo e lekanyelitsoeng ea lirafshoa tsa SiC tse fumanoeng li kholo ho feta 95% ea tekano ea theory, mme boholo ba lijo-thollo bo nyane le boholo bo tloaelehileng.Ke 1.5 microns.

Mocheso o chesang oa sintering

SiC e hloekileng e ka tšeloa ka har'a mocheso o phahameng haholo ntle le li-additives tsa sintering, kahoo batho ba bangata ba kenya ts'ebetso e chesang ea sintering bakeng sa SiC.Ho bile le litlaleho tse ngata mabapi le ho penya ho chesang ha SiC ka ho kenyelletsa lithuso tsa sintering.Alliegro et al.E ithutile phello ea boron, aluminium, nickel, tšepe, chromium le lisebelisoa tse ling tsa tšepe ho SiC densification.Liphetho li bonts'a hore aluminium le tšepe ke li-additives tse sebetsang ka ho fetesisa ho khothaletsa SiC hot pressing sintering.FFlange e ithutile phello ea ho eketsa palo e fapaneng ea Al2O3 ho thepa ea SiC e hatelitsoeng ka hot.Ho nkoa hore densification ea SiC e hatelitsoeng e chesang e amana le mochine oa ho qhibiliha le pula.Leha ho le joalo, mokhoa oa ho chesa mochine o chesang o ka hlahisa likarolo tsa SiC tse nang le sebōpeho se bonolo feela.Palo ea lihlahisoa tse hlahisoang ke ts'ebetso ea nako e le 'ngoe ea ho chesa mochine oa khatiso e nyenyane haholo, e sa lumellaneng le tlhahiso ea indasteri.

Hot isostatic tobetsa sintering

E le ho hlōla mefokolo ea mokhoa oa setso oa sintering, mofuta oa B le mofuta oa C o ile oa sebelisoa e le li-additives 'me theknoloji e chesang ea isostatic pressing sintering e ile ea amoheloa.Ka 1900 ° C, ho ile ha fumanoa li-ceramics tse ntle tsa kristale tse nang le boima bo fetang 98, 'me matla a ho khumama ka mocheso oa kamore a ka fihla ho 600 MPa.Le hoja ho chesa isostatic pressing sintering e ka hlahisa lihlahisoa tse teteaneng tse nang le libopeho tse rarahaneng le thepa e ntle ea mochine, sintering e tlameha ho koaloa, e leng thata ho finyella tlhahiso ea indasteri.

Reaction sintering

Reaction sintered silicon carbide, eo hape e tsejoang e le self bonded silicon carbide, e bua ka mokhoa oo porous billet e sebetsanang le khase kapa mokelikeli ho ntlafatsa boleng ba billet, ho fokotsa porosity, le lihlahisoa tse felileng tsa sinter ka matla a itseng le ho nepahala ho itseng.nka phofo ea α- SiC le graphite li tsoakoa ka tekanyo e itseng 'me li futhumatsoa hoo e ka bang 1650 ℃ ho etsa sekoere billet.Ka nako e ts'oanang, e kenella kapa e kenella ka har'a billet ka gaseous Si 'me e itšoara ka graphite ho etsa β-SiC, e kopantsoe le likaroloana tse teng tsa α-SiC.Ha Si e kenngoa ka ho feletseng, 'mele o sintered o nang le boima bo feletseng le boholo bo sa fokotseheng bo ka fumanoa.Ha ho bapisoa le lits'ebetso tse ling tsa sintering, phetoho ea boholo ba reaction sintering ts'ebetsong ea densification e nyane, 'me lihlahisoa tse nang le boholo bo nepahetseng li ka lokisoa.Leha ho le joalo, ho ba teng ha palo e kholo ea SiC 'meleng oa sintered ho etsa hore mocheso o phahameng oa li-ceramics tsa sintered tsa SiC li mpe le ho feta.

Nako ea poso: Jun-08-2022