sebōpi se nang le khatello e tlaase ea carburizing se nang le mokhoa oa ho etsisa le oa ho laola le tsamaiso ea ho tima khase

Kopo

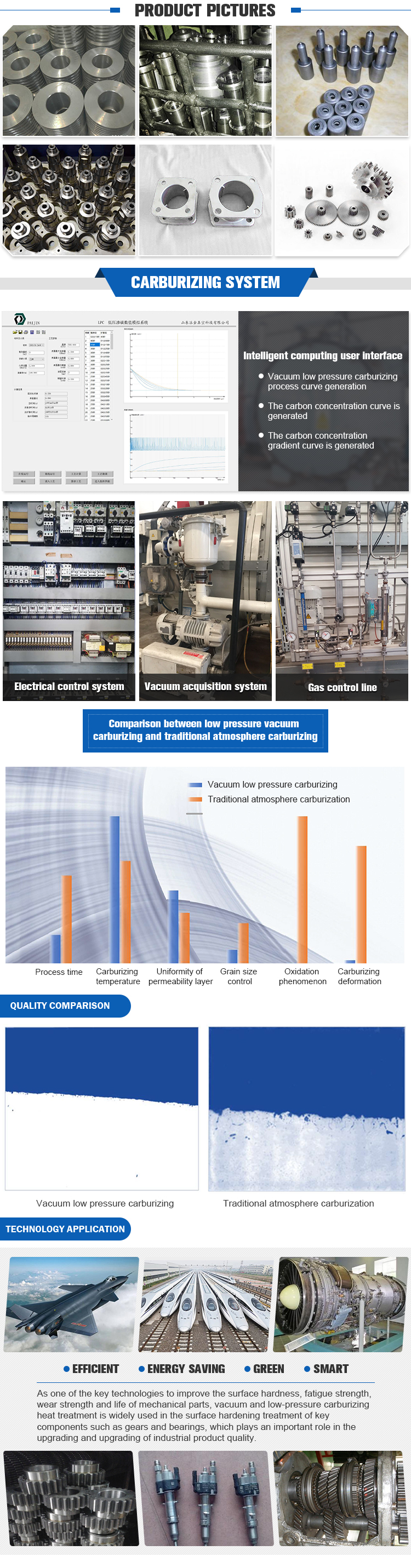

Kamore e le 'ngoe e tšekaletseng khatello e tlase Carburizing sebopi se timang khase (ho pholisa moea kamofuta oa phallo ea khase) e na le mesebetsi e mengata joalo ka carburizing, ho tima khase le khatellophodiso ya moya. Haholo-holo e sebelisoa bakeng sa quenching, annealing, tempering ea die steel, thetšepe e sa hloekang, tšepe e lebelo le phahameng, lits'ebetso tse higent joalo ka nako e le 'ngoe e phahameng ea carburizing, pulse carburizing joalo-joalo.

Sistimi ea LPC

E le thekenoloji ea bohlokoa ea ho ntlafatsa ho thatafala ha holim'a metsi, matla a mokhathala, matla a ho roala le bophelo ba tšebeletso ea likarolo tsa mochine, phekolo ea mocheso e tlaase ea khatello ea carburizing e sebelisoa haholo ho phekola ho thatafatsa holim'a likarolo tsa bohlokoa tse kang likere le li-bearings, tse phethang karolo ea bohlokoa ho ntlafatsa boleng ba lihlahisoa tsa indasteri. Vacuum low-pressure carburizing e na le litšobotsi tsa ts'ebetso e phahameng, ho boloka matla, botala le bohlale, 'me e se e le mokhoa o ka sehloohong oa carburizing o tsebahalang indastering ea kalafo ea mocheso ea China.

Software ea ketsiso e tlase ea khatello ea carburizing e ikemetseng e ntlafalitsoeng ke Shandong paijin Vacuum Technology Co., Ltd. e se e sebelisitsoe ka katleho, 'me lisebelisoa le ts'ebetso ea sebopi sa ho tima sebopi sa vacuum low-pressure carburizing quenching se thakhotsoe indastering. Morero ona o tlatsa lekhalo la hore vacuum ea lehae e tlase-khatello ea ho tima carburizing ts'ebetso le lisebelisoa li 'nile tsa itšetleha ka thepa e tsoang linaheng tse ling,' me e thehile motheo o tiileng bakeng sa nts'etsopele ea indasteri ea phekolo ea mocheso ea naha ho ntlafatsa boleng le lebelo. Sesebelisoa sa ketsiso ea ts'ebetso e na le melemo ea sistimi e bohlale ea ketsiso, lisebelisoa tsa ho kenya le litlhoko tsa ts'ebetso, ka bo eona e ntša mokhoa o ts'oanang oa carburizing laebraring ea ts'ebetso, 'me e sebetsa ho lisebelisoa tse fapaneng tse nang le phetoho e nyane. E na le melemo ea taolo e nepahetseng ea ts'ebetso, chai e ngata, deformation e nyane, boima bo ts'oanang le bo laolehang ba lera la carburized, ha ho na oxidation ea ka hare, ha ho na carbon black, ha ho na ho kenella ka hare ho sekhutlo, 'me e ka lemoha carburization ea lesoba le foufetseng. Thepa ea ts'ebetso e na le melemo ea litšenyehelo tse tlase, boleng bo phahameng le ts'ebetso e phahameng, phello ea ho boloka matla e hlakile.

Litšobotsi

1. Bohlale bo phahameng le bo sebetsang hantle. E na le software e khethehileng e ntlafalitsoeng ea vacuum low-pressure carburizing simulation.

2. Sekhahla se phahameng sa ho pholisa. sekhahla sa ho pholisa se eketsoa ka 80% ka ho sebelisa mocheso o phahameng oa lisekoere tsa mocheso.

3. Ho tšoana hantle ha pholileng. Pholiso e tšoanang ka convection e tsoang ho libapali tse peli.

4. Ho tšoana hantle ha mocheso. lintho tse futhumatsang li hlophisoa ka ho lekana likhato tse 360 ho potoloha kamore ea ho futhumatsa.

5. Ha ho na carbon black tšilafalo. Kamore ea ho futhumatsa e amohela sebopeho sa kantle sa ho kenya letsoho ho thibela tšilafalo ea carbon black ts'ebetsong ea carburizing.

6. Nako e telele ea tšebeletso ea bophelo , Ho sebelisa k'habone ho ile ha utloahala e le lera la mocheso-insulation eakamore e futhumatsang.

7. Botenya bo botle ba carburized layer, li-nozzles tsa khase ea Carburizing li hlophisitsoe ka mokhoa o lekanang ho potoloha kamore ea ho futhumatsa, 'me botenya ba lera la carburized ke junifomo.

8. Ho fokotseha ho fokolang ha mosebetsi oa Carburizing, katleho e phahameng ea tlhahiso le litšenyehelo tsa matla li bolokiloe ho feta 40%.

9. E bohlale ebile e bonolo bakeng sa lenaneo la ts'ebetso, ts'ebetso e tsitsitseng le e ka tšeptjoang ea mochine , ka tsela e iketsang, semi-automatically kapa ka letsoho e tšosang le ho bontša liphoso.

10. Maqhubu a ho sokoloha taolo ya khase quenching fan, boikhethelo convection moea futhumatsang, boikhethelo 9 lintlha mocheso phuputso e entsoeng, 'maloa limaraka le quenching isothermal.

11. Ka tsamaiso eohle ea taolo ea AI le tsamaiso e eketsehileng ea tsamaiso ea matsoho.