Vacuum carburizing sebōpi

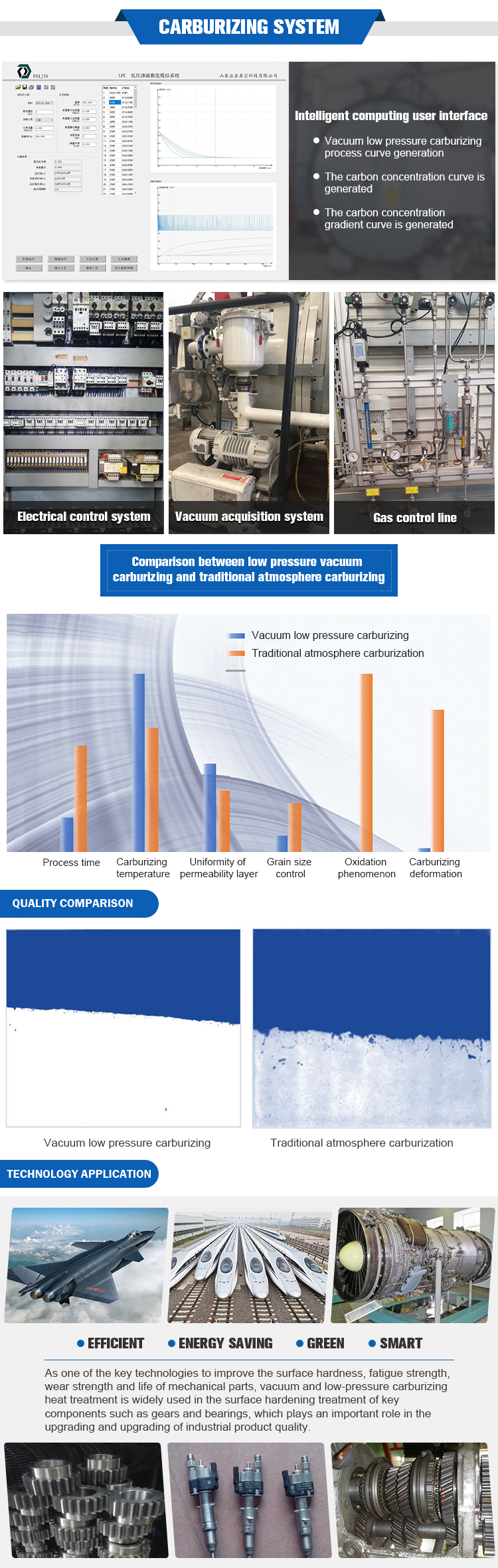

Vacuum carburizing ke ho futhumatsa sesebelisoa ka har'a vacuum.Ha e fihla mocheso ka holim'a ntlha e mahlonoko, e tla lula nako e itseng, e senya le ho tlosa filimi ea oxide, ebe e fetela ka khase e hloekisitsoeng ea carburizing bakeng sa carburizing le diffusion.Thempereichara ea carburizing ea vacuum carburizing e phahame, ho fihla ho 1030 ℃, 'me lebelo la carburizing le potlakile.Mosebetsi oa holim'a likarolo tsa carburized o ntlafatsoa ka ho senya le ho senya.Lebelo le latelang la phatlalatso le hodimo haholo.Carburizing le diffusion li etsoa khafetsa le ka tsela e fapaneng ho fihlela mahloriso le botebo bo hlokahalang bo fihla.

Botebo ba vacuum carburizing le mahloriso a holim'a metsi a ka laoloa;E ka fetola thepa ea metallurgical ea bokaholimo ba likarolo tsa tšepe, 'me botebo ba eona bo sebetsang ba carburizing bo tebile ho feta botebo ba' nete ba carburizing ea mekhoa e meng.

Tlhaloso ea Sehlahisoa

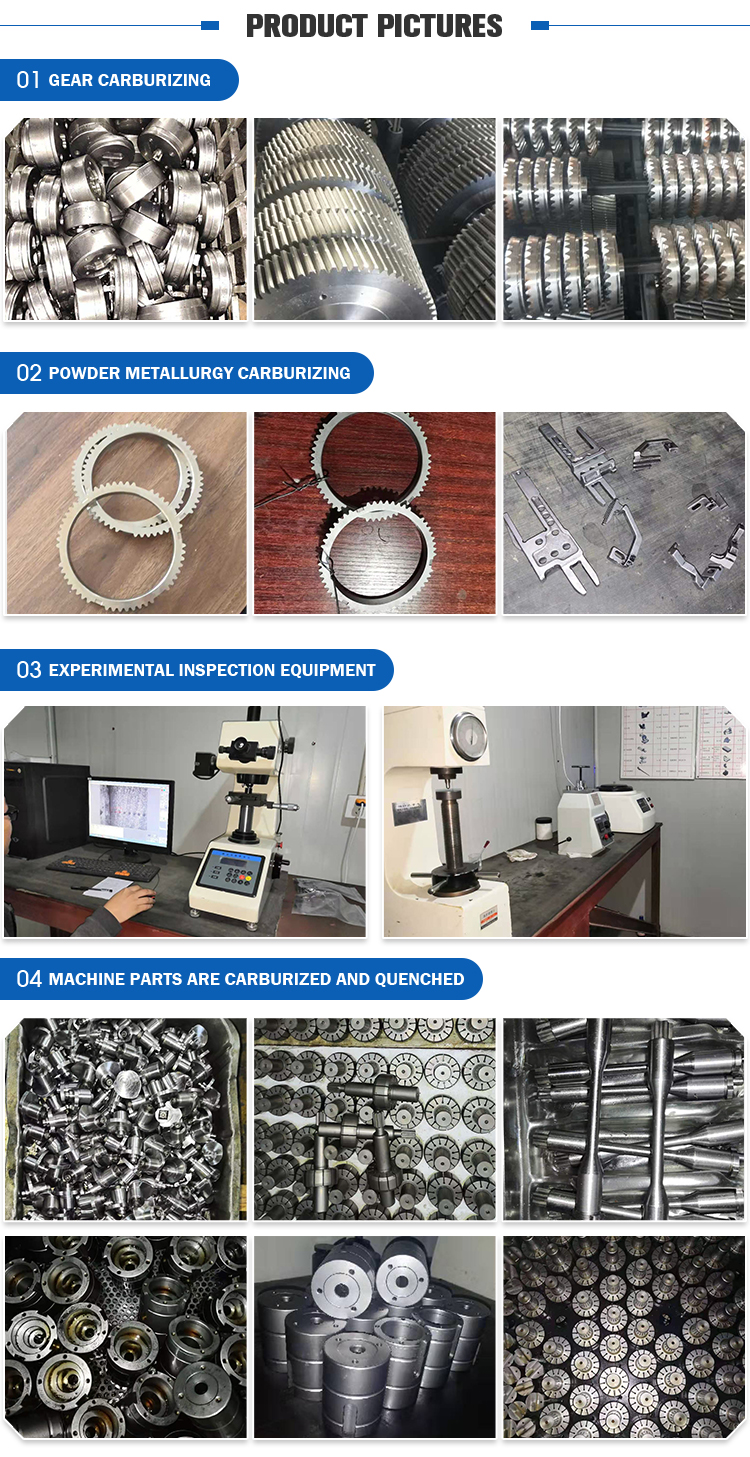

Kamore e le 'ngoe e tšekaletseng khatello e tlase Carburizing sebopi se timang khase (ho pholisa moea kamofuta oa phallo ea khase) e na le mesebetsi e mengata joalo ka carburizing, ho tima khase le khatellophodiso ya moya.

Kopo

Sebōpi sena se sebelisoa haholo bakeng sa ho tima, ho halefisa, ho futhumatsa tšepe ea die,tšepe e sa hloekang, tšepe e lebelo le phahameng, lits'ebetso tse higent joalo ka nako e le 'ngoe e phahameng ea carburizing,pulse carburizing joalo-joalo.

Litšobotsi

1. Bohlale bo phahameng le bo sebetsang hantle.E na le software e khethehileng e ntlafalitsoeng ea vacuum low-pressure carburizing simulation.

2. Sekhahla se phahameng sa ho pholisa.sekhahla sa ho pholisa se eketsoa ka 80% ka ho sebelisa mocheso o phahameng oa lisekoere tsa mocheso.

3. Ho tšoana hantle ha pholileng.Pholiso e tšoanang ka convection e tsoang ho libapali tse peli.

4. Ho tšoana hantle ha mocheso.lintho tse futhumatsang li hlophisoa ka ho lekana likhato tse 360 ho potoloha kamore ea ho futhumatsa.

5.No carbon black tšilafalo.Kamore ea ho futhumatsa e amohela sebopeho sa kantle sa ho kenya letsoho ho thibela tšilafalo ea carbon black ts'ebetsong ea carburizing.

6. Nako e telele ea tšebeletso ea bophelo , Ho sebelisa k'habone ho ile ha utloahala e le lera la mocheso-insulation eakamore e futhumatsang.

7. Botenya bo botle ba carburized layer, li-nozzles tsa khase ea Carburizing li hlophisitsoe ka mokhoa o lekanang ho potoloha kamore ea ho futhumatsa, 'me botenya ba lera la carburized ke junifomo.

8. Ho fokotseha ho fokolang ha mosebetsi oa Carburizing, katleho e phahameng ea tlhahiso le litšenyehelo tsa matla li bolokiloe ho feta 40%.

9. E bohlale ebile e bonolo bakeng sa lenaneo la ts'ebetso, ts'ebetso e tsitsitseng le e ka tšeptjoang ea mochine , ka tsela e iketsang, semi-automatically kapa ka letsoho e tšosang le ho bontša liphoso.

10. Maqhubu a ho sokoloha taolo ya khase quenching fan, boikhethelo convection moea futhumatsang, boikhethelo 9 lintlha mocheso phuputso e entsoeng, limaraka tse 'maloa le quenching isothermal.

11. Ka tsamaiso eohle ea taolo ea AI le tsamaiso e eketsehileng ea tsamaiso ea matsoho.