Sebōpi sa Vacuum Debinding and Sintering (MIM Furnace, Powder metallurgy sebōpi)

Litšobotsi

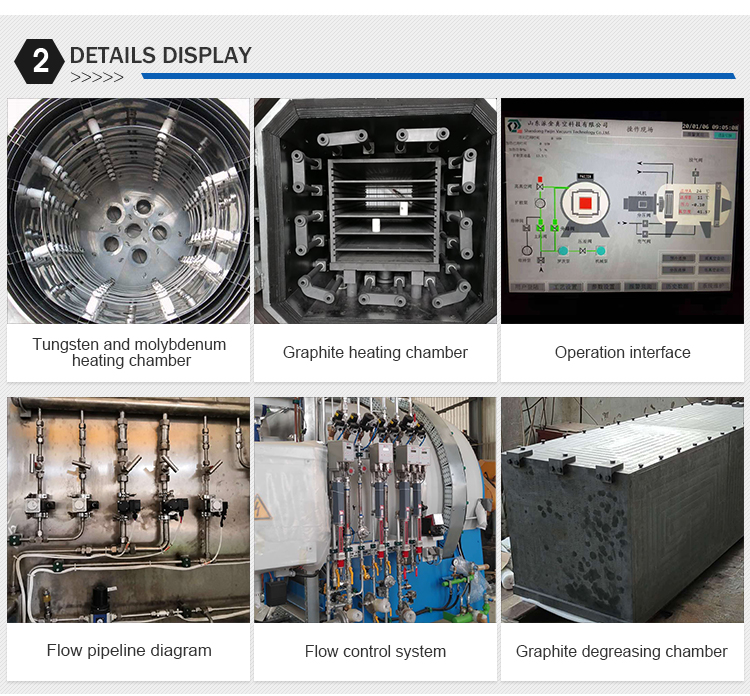

1. Letlapa la graphite insulation screen / metal screen optional, futhumatsang element 360 degree pota-potileng mahlaseli a futhumatsang, moralo o tšepahalang oa ho kenya.

2. Boemo bo phahameng ba mocheso le ho sebetsa hantle ha mocheso

3. Vacuum partial pressure / mosebetsi oa ho laola mocheso oa libaka tse ngata.

4. Thepa e ikemetseng ka botlalo, polokeho e phethahetseng le sistimi e sa tloaelehang ea alamo.

5. Taolo e nepahetseng ea ts'ebetso ho fihlela boleng ba karolo e tsitsitseng le ho thibela tšilafalo ea likarolo le libaka tse chesang.

6. Ka lebokose la degreasing le tiisitsoeng le vacuum condenser ho fokotsa tšilafalo ea kamore ea ho futhumatsa le yuniti.

7.Thibela tšilafalo ho likarolo tsa sebōpi. Lebokose la "square degreasing box" le sebelisetsoa ho sebetsana le palo e kholo ea li-additives tsa ho bopa.

8. E na le mesebetsi ea ho hula ka mokhoa o feto-fetohang oa vacuum, vacuum sintering, micro-positive pressure sintering joalo-joalo.

9. Sebopeho sa morao-rao sa ho futhumatsa mocheso le lisebelisoa li sebelisoa, khatello ea khatello e matla, 'me ho boloka matla ho hlakile.

10.E na le mesebetsi ea mocheso o feteletseng le alamo ea khatello e feteletseng, ts'ireletso ea mochine o ikemetseng oa khatello, o itekanetsengtšireletso ea liphallelo tse feteletseng, ts'ebetso ea ts'ebetso joalo-joalo, tšireletso ea thepa e phahameng.

11.Ts'ebetso ea Remote, tlhahlobo ea phoso e hole le mesebetsi ea ntlafatso ea software e hole, joalo-joalo.

Tlhaloso e tloaelehileng ea mohlala le li-parameter

| Mohlala | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Sebaka se sebetsang se chesang sa LWH (mm) | 200*200* 300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| Boima ba moroalo(kg) | 100 | 200 | 400 | 600 | 10000 |

| Matla a ho futhumatsa (kw) | 65 | 80 | 150 | 200 | 450 |

| Thempereichara e kholo(℃) | 1600 | ||||

| Ho nepahala ha taolo ea mocheso(℃) | ±1 | ||||

| Ho lumellana ha mocheso oa sebōpi(℃) | ±3 | ||||

| Degree ea vacuum ea mosebetsi (Pa) | 4.0 * E -1 | ||||

| Litefiso tsa ho pompa (ho isa ho 5 pa) | ≤10 mets | ||||

| Sekhahla sa ho phahamisa khatello (Pa/H) | ≤ 0.5 | ||||

| Sekhahla sa debinding | 97.5% | ||||

| Mokhoa oa ho kopanya | N2 ka khatello e mpe, H2 sepakapakeng | ||||

| Ho kenya khase | N2, H2, Ar | ||||

| Mokhoa oa ho pholisa | pholiso ea khase ea inert | ||||

| Sintering mokhoa | Vacuum sintering, khatello ea karolo e itseng ea sintering, sintering ntle le khatello | ||||

| Sebōpi sa sebōpi | Kamore e otlolohileng, e le 'ngoe | ||||

| Mokhoa oa ho bula lemati la sebōpi | Mofuta oa hinge | ||||

| Lintho tse futhumatsang | Lintho tse futhumatsang tsa graphite | ||||

| Kamore ea ho futhumatsa | Sebopeho sa sebopeho sa Graphit se utloileng bohloko le se bonolo | ||||

| Thermocouple | Mofuta oa C | ||||

| PLC le likarolo tsa motlakase | Siemens | ||||

| Selaoli sa mocheso | EUROTHERM | ||||

| Pompo ea vacuum | Pompo ea mochini le pompo ea metso | ||||

| Mekhahlelo e ikhethileng ea khetho | |||||

| Boholo ba mocheso | 1300-2800 ℃ | ||||

| Tekanyo e phahameng ea mocheso | 6.7 * E -3 Pa | ||||

| Sebōpi sa sebōpi | Kamore e tšekaletseng, E theohileng, Kamore e le 'ngoe | ||||

| Mokhoa oa ho bula lemati | Mofuta oa hinge, Mofuta oa ho phahamisa, Mofuta o bataletseng | ||||

| Lintho tse futhumatsang | Lintho tse futhumatsang tsa graphite, likarolo tsa ho futhumatsa tsa Mo | ||||

| Kamore ea ho futhumatsa | graphit e entsoeng e utloahala, Lisebelisoa tsohle tsa tšepe tse bonahatsang skrine | ||||

| Lipompo tsa vacuum | pompo ea mochini le pompo ea metso; Mechini, Metso le lipompo tsa diffusion | ||||

| PLC le likarolo tsa motlakase | Siemens; Omrone; Mitsubishi; Siemens | ||||

| Selaoli sa mocheso | EUROTHERM;S HIMADEN | ||||