vacuum khase e tima sebōpi E tšekaletseng ka kamore e le 'ngoe

Ke eng e timang khase ea vacuum

Ho tima khase ea vacuum ke mokhoa oa ho futhumatsa mochini oa mosebetsi tlas'a vacuum, ebe o o pholisa ka potlako ka khase e pholileng ka khatello e phahameng le lebelo le phahameng la phallo, e le ho ntlafatsa ho thatafala ha holim'a mosebetsi.

Ha ho bapisoa le ho tima khase e tloaelehileng, ho tima oli le ho tima metsi a letsoai, ho tima khase e nang le khatello e phahameng ea vacuum ho na le melemo e totobetseng: boleng bo botle ba holim'a metsi, ha ho na oxidation le carburization; E ntle quenching ho tšoana le nyenyane workpiece deformation; Taolo e ntle ea matla a ho tima le sekhahla sa ho pholisa se laolehang; Tlhahiso e phahameng, ho boloka mosebetsi oa ho hloekisa ka mor'a ho tima; Ha ho na tšilafalo ea tikoloho.

Ho na le lisebelisoa tse ngata tse loketseng ho tima khase e phahameng ea khatello, haholo-holo ho kenyelletsa: tšepe e lebelo le phahameng (joalo ka lithulusi tsa ho itšeha, libotlolo tsa tšepe, li-dies, gauges, libering bakeng sa lienjineri tsa jete), tšepe ea lisebelisoa (likarolo tsa oache, lisebelisoa, likhatiso), tšepe ea die, tšepe e behang, jj.

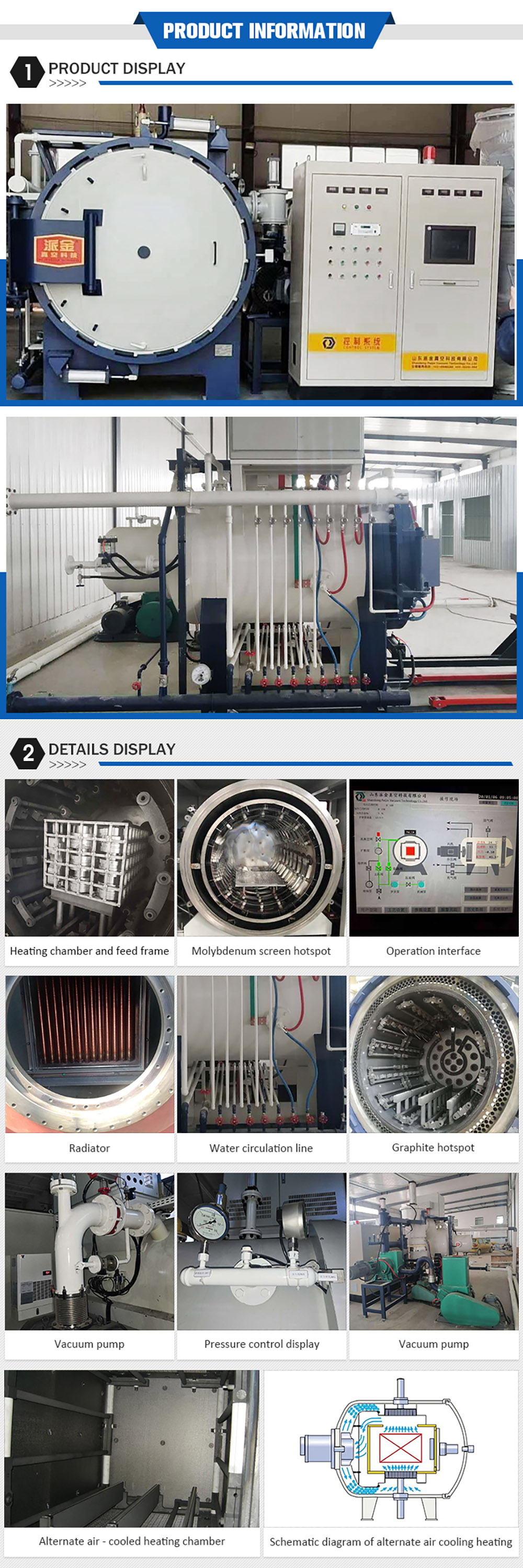

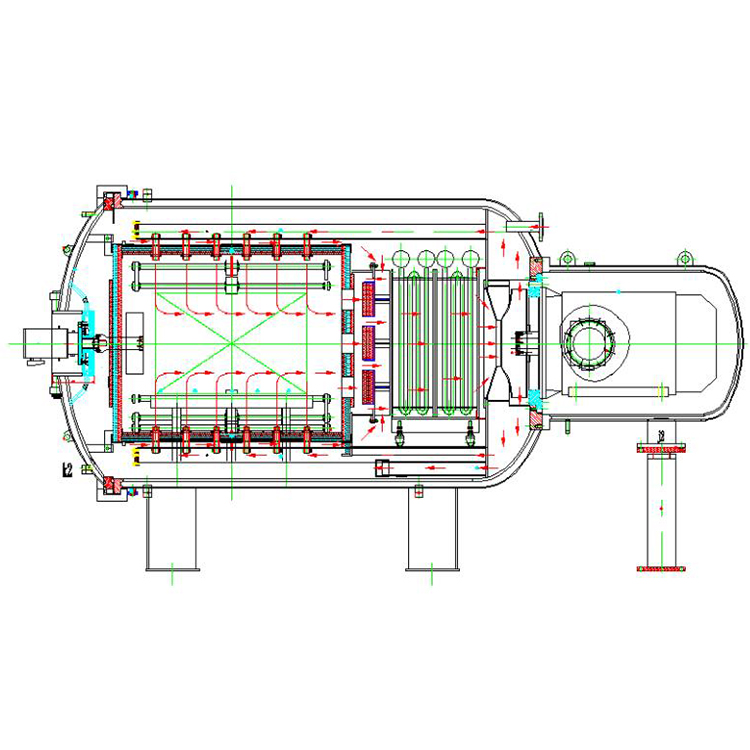

Sebōpi sa ho tima khase ea Paijin Vacuum ke sebōpi se nang le sebōpi se nang le 'mele oa sebōpi, kamore ea ho futhumatsa, mocheso o kopanyang o chesang, sistimi ea vacuum, sistimi ea ho tlatsa khase, sistimi ea taolo ea motlakase, sistimi ea pholiso ea metsi, sistimi ea ho tima khase, sistimi ea pneumatic, sistimi ea phepelo ea motlakase le mochini oa phepelo oa motlakase.

Kopo

Paijin Vacuum sebopi se timang khasee loketse bakeng sa ho tima phekolo ea thepa e kang die steel, high-speed steel, stainless steel, joalo-joalo; phekolo ea tharollo ea lisebelisoa tse kang tšepe e sa hloekang, titanium le alloy ea titanium; kalafo annealing le tempering kalafo ea tse fapa-fapaneng matla a khoheli; 'me e ka sebelisoa bakeng sa vacuum brazing le vacuum sintering.

Litšobotsi

1. Lebelo le phahameng la ho pholisa:ka ho sebelisa mocheso o phahameng oa mocheso oa lisekoere, sekhahla sa eona sa ho pholisa se eketsoa ka 80%.

2. Ho tšoana hantle ha ho pholisa:Li-nozzles tsa moea li lekana 'me li tsitsitse li behiloe ho potoloha phaposi ea ho futhumatsa.

3. Ho Boloka Matla a Phahameng:Li-nozzles tsa eona tsa moea li tla koala ka bo eona ts'ebetsong ea ho futhumatsa, e etsa hore matla a eona a fokotsehe ka 40%.

4. Ho tšoana hantle ha mocheso:likarolo tsa eona tsa ho futhumatsa li behiloe ka ho lekana ho pota-pota kamore ea ho futhumatsa.

5. E loketse maemo a fapaneng a ts'ebetso:Lera la eona la ho futhumatsa la kamore ea ho futhumatsa le entsoe ka sekoaelo se thata sa insulating kapa sekoaelo sa tšepe, se loketseng libaka tse fapaneng.

6. E bohlale ebile e bonolo bakeng sa lenaneo la ts'ebetso, ts'ebetso e tsitsitseng le e ka tšeptjoang ea mochine, ka ho iketsa, semi-automatically kapa ka letsoho e tšosang le ho bontša liphoso.

7. Phetoho ea phetolo ea phetolo ea khase e timang fan, ho futhumatsa moea ka boikhethelo, tlhahlobo ea mocheso ea lintlha tse 9, ho tima khatello e itseng le ho tima ha isothermal.

8. Ka tsamaiso eohle ea taolo ea AI le tsamaiso e eketsehileng ea tsamaiso ea matsoho.

Tlhaloso e tloaelehileng ea mohlala le li-parameter

| Tlhaloso e tloaelehileng ea mohlala le li-parameter | |||||

| Mohlala | PJ-Q557 | PJ-Q669 | PJ-Q7711 | PJ-Q8812 | PJ-Q9916 |

| Effective Hot Zone LWH (mm) | 500*500 * 700 | 600*600 * 900 | 700*700 * 1100 | 800*800 * 1200 | 900*900 * 1600 |

| Boima ba Mojaro(kg) | 300 | 500 | 800 | 1200 | 2000 |

| Boholo ba Mocheso(℃) | 1350 | ||||

| Ho nepahala ha taolo ea mocheso(℃) | ±1 | ||||

| Ho lumellana ha mocheso oa sebōpi(℃) | ±5 | ||||

| Maximum Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Sekhahla sa ho phahamisa khatello (Pa/H) | ≤ 0.5 | ||||

| Khatello ea ho tima khase (Bar) | 10 | ||||

| Sebōpi sa sebōpi | Kamore e otlolohileng, e le 'ngoe | ||||

| Mokhoa oa ho bula lemati la sebōpi | Mofuta oa hinge | ||||

| Lintho tse futhumatsang | Lintho tse futhumatsang tsa graphite | ||||

| Kamore ea ho futhumatsa | Sebopeho sa sebopeho sa Graphit se utloileng bohloko le se bonolo | ||||

| Mofuta oa phallo ea ho tima khase | Phallo e emeng e fapanyetsanang | ||||

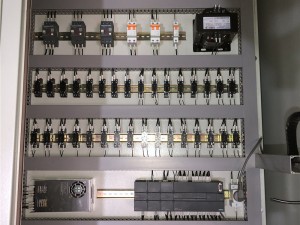

| PLC le Lisebelisoa tsa Motlakase | Siemens | ||||

| Selaoli sa mocheso | EUROTHERM | ||||

| Pompo ea vacuum | Pompo ea mochini le pompo ea metso | ||||

| Mekhahlelo e ikhethileng ea khetho | |||||

| Boholo ba mocheso | 600-2800 ℃ | ||||

| Tekanyo e phahameng ea mocheso | 6.7 * E -3 Pa | ||||

| Khatello ea ho tima khase | 6-20 Bar | ||||

| Sebōpi sa sebōpi | Kamore e otlolohileng, e otlolohileng, e le 'ngoe kapa likamore tse ngata | ||||

| Mokhoa oa ho bula lemati | Mofuta oa hinge, mofuta oa ho phahamisa, mofuta o bataletseng | ||||

| Lintho tse futhumatsang | Lintho tse futhumatsang tsa graphite, likarolo tsa ho futhumatsa tsa Mo | ||||

| Kamore ea ho futhumatsa | Sebopeho sa Graphite se ile sa utloahala, Lisebelisoa tsohle tsa tšepe tse bonahatsang skrine | ||||

| Mofuta oa phallo ea ho tima khase | Phallo ea khase e tšekaletseng e tšekaletseng; | ||||

| Lipompo tsa vacuum | pompo ea mochini le pompo ea metso; Mechini, metso le lipompo tsa phallo | ||||

| PLC le Lisebelisoa tsa Motlakase | Siemens;Omron;Mitsubishi;Siemens | ||||

| Selaoli sa mocheso | EUROTHERM;SHIMADEN | ||||

Taolo ea boleng

Boleng ke moea oa lihlahisoa, ke ntlha ea bohlokoa ho etsa qeto ea fektheri's future.Paijin nka boleng e le litaba tse tlang pele ka ho fetisisa mosebetsing oa rona oa letsatsi le letsatsi.Ho netefatsa boleng bo botle ba lihlahisoa tsa rona, re ile ra ela hloko haholo lintlha tse 3.

1.Habohlokoa ka ho fetisisa: Motho. Motho ke ntlha ea bohlokoa ka ho fetisisa mosebetsing o mong le o mong. Re na le lithupelo tse felletseng bakeng sa mosebeletsi e mong le e mong e mocha, 'me re na le mokhoa oa ho fana ka litekanyetso ho lekanya mosebeletsi e mong le e mong ho ea boemong (e monyenyane, bohareng, bo phahameng), basebetsi ba maemo a fapaneng ba khetheloa mesebetsi e fapaneng ka meputso e fapaneng. Tsamaisong ena ea litekanyetso, e's eseng feela litsebo, empa le tekanyo ea boikarabelo le tekanyo ea liphoso, matla a phethahatso joalo-joalo Ka tsela ena, basebetsi ba fektheri ea rona ba ikemiselitse ho etsa se molemo ka ho fetisisa mosebetsing oa hae.Mme o latela ka tieo melao ea tsamaiso ea boleng.

2. Lisebelisoa le likarolo tse ntle ka ho fetisisa: Re reka feela lisebelisoa tse ntle ka ho fetisisa 'marakeng, rea tseba hore ho boloka $ 1 ka thepa ho ka bitsa lidolara tse 1000 qetellong. Likarolo tsa bohlokoa tse kang likarolo tsa motlakase le lipompo kaofela ke lihlahisoa tsa brand tse kang Siemens, Omron, Eurotherm, Schneider joalo-joalo Bakeng sa likarolo tse ling tse entsoeng Chaena, re khetha fektheri e ntle ka ho fetisisa indastering le ho saena konteraka ea boleng ba sehlahisoa sa guranntee le bona, ho etsa bonnete ba hore karolo e 'ngoe le e' ngoe eo re e sebelisang ka sebōping ke lihlahisoa tsa boleng bo botle ka ho fetisisa.

3. Tsamaiso e tiileng ea Boleng: Re na le lintlha tsa ho hlahloba boleng ba 8 lits'ebetsong tsa tlhahiso ea sebōpi, Tlhahlobo sebakeng se seng le se seng sa tlhahlobo e tsamaisoa ke basebetsi ba 2 mme mookameli oa fektheri oa 1 o ikarabella bakeng sa eona. Lintlheng tsena tsa ho hlahloba, lisebelisoa le likarolo, le likarolo tsohle tsa sebōpi li hlahlojoa habeli ho netefatsa boleng ba tsona. Qetellong, pele sebōpi se tloha fekthering, se lokela ho hlahlojoa ka ho feletseng ka liteko tsa phekolo ea mocheso.